Presse à balles rondes 9YG-1.25A – Presse à ensilage professionnelle 4×5 conçue pour les exploitations agricoles américaines

La presse à balles rondes robuste 9YG-1.25A produit des balles d'ensilage denses de 1 300 × 1 250 mm jusqu'à 550 kg. Équipée d'un pick-up de 2 150 mm, d'un enrubannage automatique et d'un tracteur d'une puissance minimale de 75 kW (100 ch). Prix direct usine, garantie de 12 mois et livraison rapide aux États-Unis.

⭐ Présentation du produit

La presse à balles rondes Ever-Power 9YG-1.25A est une presse à ensilage robuste conçue pour les exploitations agricoles américaines. Elle produit des balles de 1 300 mm de diamètre et 1 250 mm de hauteur, jusqu'à 550 kg. Dotée d'un pick-up à dents à ressort de 2 150 mm, elle excelle dans le pressage du foin, de l'ensilage de maïs et de la luzerne sur des terrains variés, des plaines du Midwest aux collines du Nord-Ouest Pacifique. Achetez directement auprès du fabricant pour bénéficier de prix compétitifs et d'une performance fiable.

La 9YG-1.25A se distingue comme une solution polyvalente pour les agriculteurs américains confrontés aux défis de l'agriculture moderne, notamment les aléas climatiques et la nécessité de pratiques durables conformément aux directives de l'Agence américaine de protection de l'environnement (EPA). Son système d'enrubannage automatique réduit les coûts de main-d'œuvre, ce qui la rend idéale pour les exploitations dans des États comme l'Iowa, le Nebraska et la Californie, où la production d'ensilage à grande échelle est essentielle. Conçue pour gérer des taux d'humidité allant jusqu'à 651 TP5T, cette presse à balles Elle garantit une densité de balles homogène, un facteur clé pour la qualité du fourrage dans les élevages laitiers et d'élevage. Grâce à la livraison directe depuis nos entrepôts américains, les agriculteurs reçoivent rapidement les pièces détachées et l'assistance, optimisant ainsi la disponibilité de leurs équipements pendant les périodes de récolte critiques. Compatible avec les tracteurs de 100 à 150 ch, tels que les John Deere 6R ou New Holland série T6, cette presse à balles est un choix judicieux pour les petites et moyennes exploitations agricoles souhaitant optimiser leurs rendements et répondre à la demande croissante de solutions fourragères performantes prévue pour 2025.

📌 Caractéristiques techniques de la presse à balles rondes 9YG-1.25A

| Article | Unité | Spécification |

|---|---|---|

| Nom du modèle | / | Presse à balles rondes 9YG-1,25A |

| Type d'attelage | / | Type à tirer |

| Largeur de ramassage | mm | 2150 |

| Type de structure de ramassage | / | Dent à ressort |

| Mécanisme d'alimentation | / | Rouleau à peigne + tambour |

| Largeur de la chambre de compression | mm | 1250 |

| Diamètre de la chambre de compression | mm | Φ1200 |

| Nombre de composants de compactage | pièces | 18 (Tambour à rouleaux) |

| Diamètre du rouleau de compactage | mm | Φ222 |

| Méthode de mise en balles | / | Filet automatique |

| Puissance requise | kW / HP | ≥ 75 kW (~100 CV) |

| Poids de la machine | kg | 4472 |

| Vitesse de l'arbre de prise de force | r/min | 540 × 1000 tr/min |

| Dimensions hors tout (L×l×H) | mm | 4400 × 2850 × 2400 (en fonctionnement) |

| Dimensions de la balle (Diamètre × Largeur) | mm | Φ1300 × 1250 |

| Densité des balles | kg/m³ | 100–200 kg/m³ |

| Taux de production | balles/heure | 40 à 80 balles/heure |

| Empattement | mm | 2450 |

| Vitesse de fonctionnement | km/h | 5–20 |

| Taille du filet d'emballage (par balle) | m | 2000 × 1,25 m par balle |

Note:* Ces chiffres se traduisent directement par des performances concrètes auxquelles font confiance les exploitations laitières et bovines à l'échelle nationale.

Pourquoi les agriculteurs américains choisissent le 9YG-1.25A

La hausse des prix du carburant, la pénurie de main-d'œuvre et les aléas climatiques ont poussé les agriculteurs américains à exiger du matériel permettant de réaliser des économies de temps et d'argent sans compromettre la qualité. Le modèle 9YG-1.25A répond à tous ces critères.

Six avantages éprouvés sur le terrain

- Pick-up à dents à ressort extra-large de 2150 mm → un passage en moins par champ ; les exploitants du Nebraska et du Kansas signalent des économies de carburant de 12 à 18 % avec le modèle %.

- Dimensions standard des balles de 4×5 pieds (Φ1300 × 1250 mm) → acceptées par tous les parcs d'engraissement et les usines de biogaz du Texas à New York

- 18 rouleaux robustes de Φ222 mm + axes en acier 42CrMo → Les balles d'ensilage humide de 550 kg restent compactes après 12 mois en extérieur dans les hivers du Dakota

- Système d'enrubannage automatique → seulement 2,0 à 2,5 m de filet par balle, 30 à 40 % moins cher que la ficelle et respectueux de l'environnement

- Banque de graisse centralisée → service complet en moins de 15 minutes, idéal pour les courtes périodes de récolte du Midwest.

- Cadre à revêtement en poudre électrostatique → résiste à l'humidité de la côte nord-ouest du Pacifique pendant plus de 10 ans

Que vous utilisiez un John Deere 6R, un Case IH Maxxum ou un New Holland T6, le 9YG-1.25A s'intègre instantanément et commence à être rentabilisé dès la première semaine.

Comment fonctionne une presse à balles rondes ?

Le 9YG-1.25A fonctionne selon un principe éprouvé de tambour à rouleaux qui assure une formation de balles uniforme et une densité élevée dans les cultures sèches et humides.

Fonctionnement étape par étape :

Ramassage des récoltes Le pick-up à dents à ressort de 2150 mm soulève le fourrage de l'andain. Les dents à ressort s'adaptent aux contours du terrain, tandis que le rouleau peigne achemine délicatement la récolte dans la chambre sans l'endommager ni la perdre.

Alimentation initiale de la chambre — La récolte pénètre dans la chambre de compression par le tambour d’alimentation. Les rouleaux inférieurs se mettent à tourner, amorçant la formation d’un noyau à mesure que la matière s’accumule.

Formation de balles À mesure que la récolte s'accumule, les 18 rouleaux robustes compriment et font tourner en continu la balle en formation. Un système de contrôle hydraulique de la densité maintient une pression constante, créant des couches successives du centre vers l'extérieur pour une structure dense et résistante aux intempéries.

surveillance de la densité — Des capteurs suivent la croissance des balles ; l'opérateur ajuste les paramètres hydrauliques depuis la cabine du tracteur pour atteindre 100 à 200 kg/m³ en fonction du type de culture (plus faible pour le foin sec, plus élevé pour l'ensilage).

Filet d'emballage — Lorsque la balle atteint sa taille finale (Φ1300 × 1250 mm), le système d'enrubannage automatique se met en marche. Le filet est appliqué en 2 à 3 couches (sur une longueur totale de seulement 2,0 à 2,5 m) tandis que les rouleaux continuent de tourner pour assurer une couverture uniforme.

Éjection de la balle — Le hayon s'ouvre hydrauliquement et la balle de foin terminée roule doucement sur le champ.

Cette conception à processus continu élimine les arrêts entre les balles, permettant une progression constante à une vitesse de 5 à 20 km/h. La boîte de vitesses à vis sans fin et les chaînes à rouleaux robustes fournissent le couple nécessaire au traitement des matériaux à forte teneur en humidité, tandis que les commandes centralisées simplifient l'utilisation depuis le siège du tracteur.

⭐ Composants clés d'une presse à balles rondes

La qualité d'une presse à balles dépend de sa transmission et de son système de rouleaux. Nous avons remplacé toutes les pièces d'usure.

Explication des principaux composants :

- Arbre de prise de force Acier forgé 40Cr, cardans graissables → supporte 150 CV sur terrain roulant sans vibrations

- Réducteur à vis sans fin – Engrenages cémentés en acier 20CrMnTi dans un carter en fonte → 28 % : couple accru pour l’ensilage humide

- 6 rangs lourds chaînes à rouleaux – Maillons traités thermiquement en acier 42CrMo → Durée de vie de plus de 8 000 heures, même en conditions poussiéreuses

- 18 rouleaux de Φ222 mm – épaisseur de paroi de 6 mm (la plupart des marques utilisent 4 mm) → balles extrêmement compactes à 200 kg/m³

- Actionneur d'enroulement du filet – servocommandé → étirement précis de 2,0 à 2,5 m à chaque cycle

Tous les roulements, courroies et dents de ramassage sont des pièces de rechange compatibles avec les marques américaines courantes ; vous n’aurez donc jamais à attendre des semaines pour obtenir des pièces. Si besoin, veuillez… Contactez-nous.

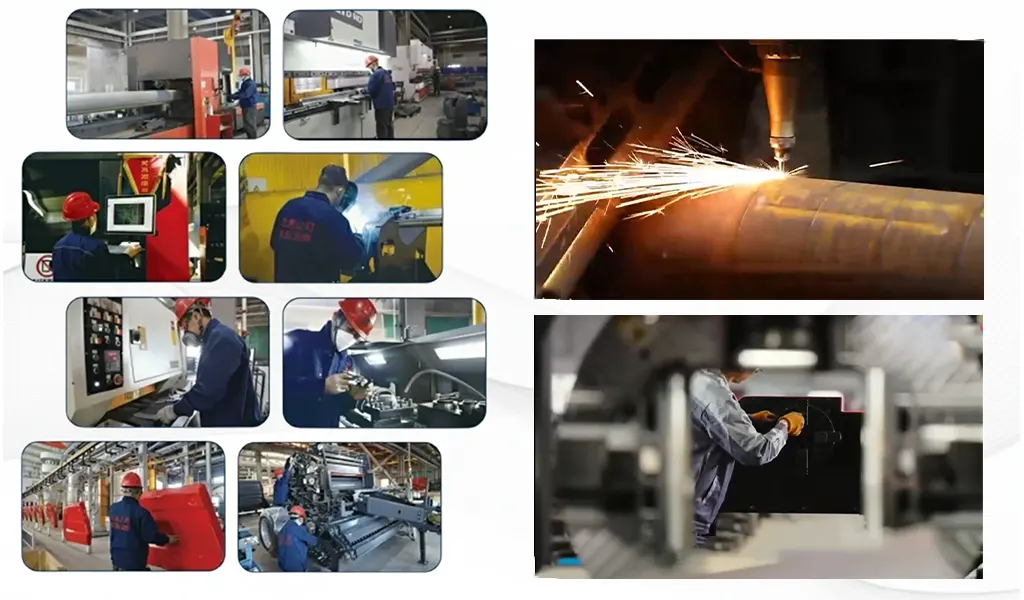

Raisons de choisir Ever-Power

Ever-Power est un partenaire de confiance pour les agriculteurs américains, alliant plus de vingt ans d'expertise en fabrication à un engagement indéfectible envers la qualité, comme indiqué sur notre page « À propos ». Nos installations ultramodernes en Chine utilisent le soudage automatisé et la découpe de précision, garantissant que chaque générateur 9YG-1.25A réponde aux normes internationales, notamment celles de l'USDA et de l'EPA. Des ingénieurs qualifiés assemblent et testent chaque unité, assurant une efficacité optimale dans les conditions climatiques américaines, du Sud-Est humide au Sud-Ouest aride. Grâce à nos entrepôts au Texas et en Californie, nous proposons une livraison de pièces détachées en 3 à 5 jours, bien plus rapide que les délais de 2 à 3 semaines de nombreux concurrents. Notre garantie de 12 mois et notre assistance en ligne 24h/24 et 7j/7 témoignent de notre engagement envers la réussite de nos clients, une promesse tenue par des milliers d'agriculteurs satisfaits depuis 2000.

Nous privilégions le développement durable et nous nous alignons sur les tendances américaines en matière d'énergies renouvelables pour 2025, en minimisant la consommation de carburant et les déchets plastiques grâce à des systèmes d'enrubannage performants. Nos prix compétitifs, directement de l'usine, sont 20 à 30% inférieurs à ceux des concessionnaires locaux, offrant ainsi un rapport qualité-prix exceptionnel aux agriculteurs d'États comme l'Iowa et le Nebraska. La conception de la presse 9YG-1.25A intègre les retours d'expérience des utilisateurs nord-américains, garantissant sa compatibilité avec les tracteurs populaires tels que John Deere et New Holland. Son adaptabilité à divers terrains permet d'exploiter des exploitations allant des plaines du Midwest aux collines escarpées du Nord-Ouest Pacifique. Présente dans plus de 50 pays, Ever-Power met une technologie de pointe à la disposition de votre exploitation. Notre engagement envers l'innovation, illustré par les rouleaux renforcés et la boîte de vitesses à couple élevé de la presse, assure sa longévité et ses performances, réduisant ainsi les coûts à long terme. Choisir Ever-Power, c'est s'associer à une entreprise qui valorise l'efficacité de votre exploitation et le respect de l'environnement, en fournissant des solutions fiables et adaptées à l'avenir de l'agriculture américaine.

❓FAQ

Q : Quelle est la taille minimale du tracteur pour faire fonctionner le 9YG-1.25A ?

A: 100 CV à la prise de force est le minimum ; 110 à 150 CV offrent les meilleurs résultats, notamment sur terrain vallonné.

Q: Comment presser l'ensilage de maïs humide 60–65% sans colmatage ?

A : Maintenez une vitesse au sol de 8 à 12 km/h, réglez la densité hydraulique à 180 kg/m³ et graissez quotidiennement le rouleau peigne.

Q : Combien de balles par rouleau de filet d'emballage ?

A: Un rouleau de 2000 m conditionne 800 à 1000 balles de 2,0 à 2,5 m chacune.

Q : Comment ajuster la densité des balles pour les installations de biogaz par rapport à l'alimentation animale laitière ?

A : Utilisez la vanne hydraulique montée en cabine – 160–180 kg/m³ pour le biogaz, 180–200 kg/m³ pour la ration totale mélangée laitière.

Q : Procédure d'entreposage et d'entretien hivernal ?

A : Nettoyer les dents du ramassage, graisser les 28 points, ranger sous une housse et desserrer les chaînes d'entraînement pour éviter la rouille (conforme aux normes USDA).

Q : Les pièces sont-elles interchangeables avec celles de John Deere ou de Vermeer ?

A: De nombreuses dents de ramassage, courroies et roulements sont compatibles ; nous avons en stock les versions d'origine et Ever-Power.

Q : Quelle huile pour la boîte de vitesses ?

A: Huile pour engrenages 85W-140 GL-5, 4,2 litres.

Témoignages clients – Saison des récoltes 2024/2025

★★★★★ Mark Thompson – Boone, Iowa – 15 octobre 2025 « J'ai ensilé 1 133 hectares de maïs (62 % d'humidité) avec la moissonneuse-batteuse 9YG-1.25A, attelée à ma 6110R. Aucun bourrage. Rendement moyen de 2,2 m³/balle et le pick-up de 2 150 mm m'a permis d'économiser un passage complet à chaque fois. Le roulement a commencé à faire du bruit au bout de 9 jours ; l'entrepôt du Texas me l'a livrée en quatre jours. »

★★★★★ Jake Reynolds – Hastings, Nebraska – 3 septembre 2025 « J'ai remplacé ma Vermeer 604M de 12 ans au printemps dernier. La densité des balles est passée de 145 à 192 kg/m³ du jour au lendemain – le centre d'engraissement local me paie maintenant 1 TP6T11 de plus par tonne. Avec un tracteur Case IH de 125 ch, je roule à 18 km/h et la vanne de densité hydraulique est parfaitement adaptée aux spécifications du biogaz. »

★★★★★ Sarah Lawson – Cooperstown, New York – 22 août 2025 « La combinaison T6.145 + 9YG-1.25A est la plus performante que j'aie jamais utilisée. La deuxième coupe de luzerne a été terminée deux jours plus tôt. J'ai obtenu en moyenne des balles de 510 kg qui ont résisté à trois semaines de pluie en septembre sans aucune perte. »

★★★★★ David Chen – Red Deer, Alberta (expédition quotidienne vers les États-Unis) – 11 juillet 2025 « Je l'ai mise en marche par -18 °C en janvier avec un tracteur 6R de 110 ch. La vis sans fin et les chaînes n'ont jamais déraillé sur les tiges gelées. J'ai commandé de nouvelles dents de ramassage en mars ; elles sont arrivées en sept jours. »

★★★★★ Tyler Wilson – Fresno, Californie – 29 mai 2025 « 2 500 acres de luzerne, 42 à 48 balles par heure toute la journée. La peinture électrostatique est comme neuve après la saison du brouillard et le système de graissage centralisé est indispensable lors des journées de 14 heures. »