Pressa per balle rotonde 9YG-1.0 – Pressa per balle di insilato per la raccolta di fieno e foraggio

Scopri la rotopressa 9YG-1.0 in vendita, progettata per piccoli trattori con pick-up a denti elastici e densità controllata tramite sensore che raggiunge i 115-200 kg/m³. Questa rotopressa supporta la lavorazione versatile di paglia di mais, riso, grano e soia nelle aziende agricole statunitensi a prezzi competitivi.

⭐ Panoramica del prodotto

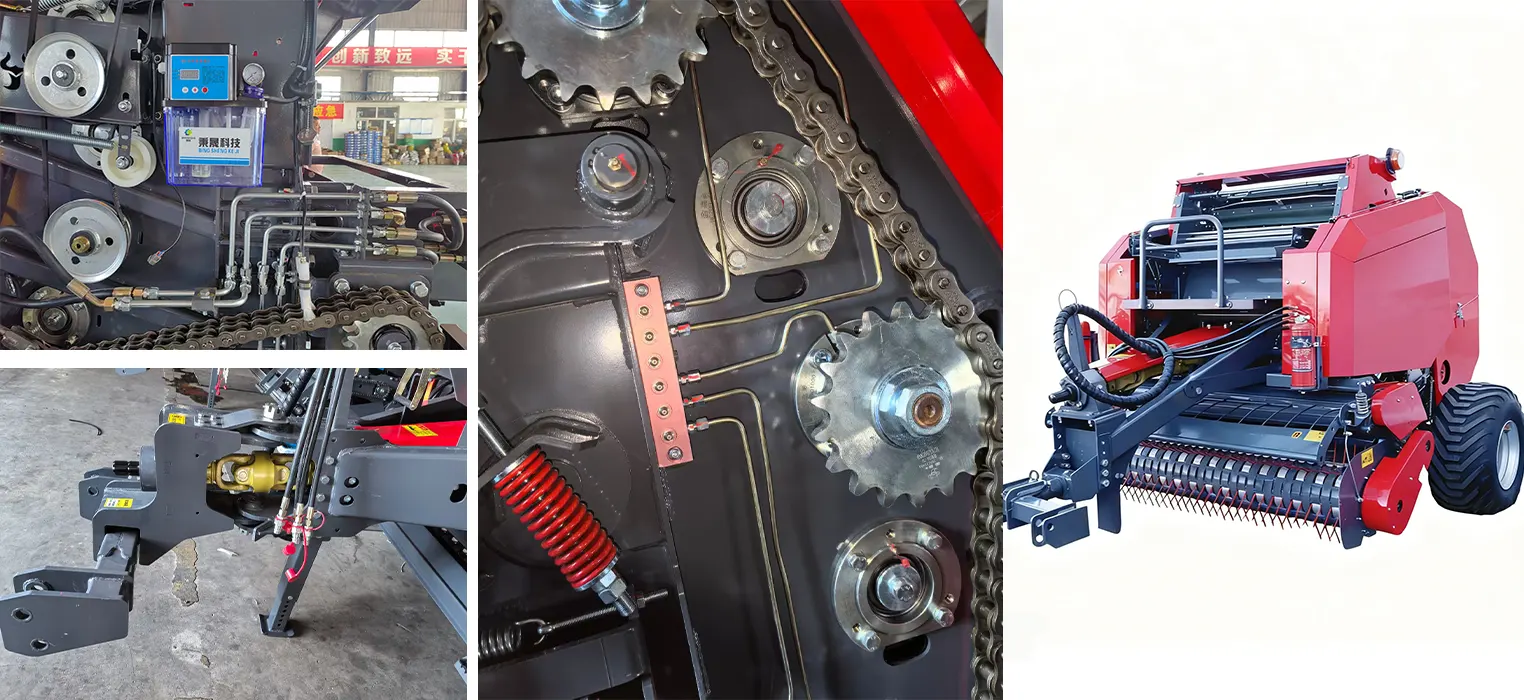

La rotopressa 9YG-1.0 rappresenta un'apparecchiatura specializzata, ottimizzata per la lavorazione della paglia nei contesti agricoli statunitensi, in particolare laddove la gestione efficiente delle risorse è in linea con le direttive federali sulla sostenibilità. Integra una struttura di raccolta a denti elastici per facilitare la raccolta precisa di fieno e foraggio, integrata da un rullo a dita e un alimentatore a tamburo per un trasporto affidabile del materiale.

La camera di compressione a tamburo, con dimensioni di 1000 mm sia in larghezza che in diametro, impiega 18 tamburi rotanti per la formazione di balle tramite legatura a rete. Questa configurazione è conforme agli standard ambientali statunitensi che danno priorità alla riduzione degli sprechi, in conformità con i protocolli USDA per l'efficienza agricola. Adatta a trattori con potenza compresa tra 48 e 80 kW, raggiunge densità di 115-200 kg/m³, soddisfacendo esigenze di stoccaggio prolungate in diverse zone climatiche.

📌 Specifiche tecniche

Per aiutarti a valutare la pressa per insilato 9YG-1.0 in base alle tue esigenze agricole, la tabella seguente ne illustra i principali parametri tecnici, tra cui dimensioni, requisiti di potenza e parametri prestazionali. Queste specifiche garantiscono la compatibilità con le attrezzature agricole standard statunitensi e la conformità agli standard di settore come la ISO 11001 per l'efficienza di compressione. Per una consulenza personalizzata sull'integrazione con le tue attività, contattaci. contatta il nostro team.

| NO. | Parametro | Unità | Valore |

|---|---|---|---|

| 1 | Nome del modello | / | Pressa rotonda 9YG-1.0 |

| 2 | Metodo di aggancio | / | Trattivo |

| 3 | Larghezza di ripresa | mm | 1900 |

| 4 | Tipo di struttura di ritiro | / | Tipo di dente a molla |

| 5 | Tipo di struttura dell'alimentatore | / | Rullo a dita + tipo a tamburo |

| 6 | Tipo di meccanismo di pressatura della camera di compressione | / | Tipo di tamburo |

| 7 | Larghezza della camera di compressione | mm | 1000 |

| 8 | Diametro della camera di compressione | mm | Φ1000 |

| 9 | Numero di parti rotanti funzionanti | pc | 16 (Tamburo) |

| 10 | Diametro del tamburo rotante | mm | Φ222 |

| 11 | Metodo di imballaggio | / | Avvolgimento in rete |

| 12 | Potenza corrispondente | kW | 48~80 |

| 13 | Massa strutturale | kg | 2640 |

| 14 | Velocità dell'albero di presa di forza | giri/min | 720 |

| 15 | Dimensioni complessive (L×P×A) | mm | 3750×2300×2020 (Stato di lavoro) |

| 16 | Controllo della densità delle balle | / | Controllo del sensore |

| 17 | Dimensioni della balla (diametro × larghezza) | mm | Φ1100×1000 |

| 18 | Densità della balla | kg/m³ | 115~200 |

| 19 | Produttività | balle/h | 40~100 |

| 20 | Passo | mm | 2045 |

| 21 | Velocità operativa | Km/h | 5-20 |

| 22 | Specifiche nette (lunghezza × larghezza) | M | 2000×1,0 m/balla |

Le specifiche sopra riportate dimostrano la robustezza del modello 9YG-1.0, progettato per un'efficiente lavorazione di fieno e foraggio, con caratteristiche ottimizzate per la produttività e la durata in diversi ambienti statunitensi. Se questi parametri corrispondono alle vostre esigenze o se necessitate di ulteriori dettagli sulle opzioni di personalizzazione, vi invitiamo a contattare i nostri esperti per una consulenza. consulenza o preventivo.

Caratteristiche principali della rotopressa 9YG-1.0

La rotopressa 9YG-1.0 è progettata per l'utilizzo con trattori di piccole dimensioni, con consumi energetici ridotti rispetto ai modelli precedenti per una maggiore efficienza. Include un dispositivo di alimentazione aggiornato e sette funzionalità personalizzate per migliorarne l'usabilità in diverse applicazioni colturali, come il recupero di paglia di mais, riso, grano e soia. Sviluppata attraverso una ricerca indipendente con un'elevata tutela della proprietà intellettuale, questa macchina produce balle uniformi con una densità di 115-200 kg/m³, per garantire la qualità del foraggio e ridurre al minimo i costi operativi.

Tabella di compatibilità

| Aspetto di compatibilità | Dettagli |

|---|---|

| Marche di trattori | Adatto ai trattori John Deere serie 5E, New Holland T5 e Massey Ferguson 4700 con configurazioni PTO standard. |

| Standard PTO | Compatibile con ASABE S318 per alberi cardanici a 6 scanalature da 1-3/8", comuni nelle apparecchiature statunitensi. |

| Tipi di colture | Lavora fieno secco, insilato umido e paglia di mais, riso, grano e soia; intercambiabile con la serie Claas Rollant per densità di produzione simili. |

| Opzioni di sostituzione | Rappresenta un aggiornamento rispetto ai vecchi modelli McHale F5000, con alimentazione migliorata per la versatilità di più colture. |

| Flangia e montaggio | Utilizza gli standard ANSI B92.1 per scanalature e modelli a 4 bulloni per rapidi attacchi agricoli negli Stati Uniti. |

Contrasti standard del settore

| Parametro | Valore 9YG-1.0 | Norma ISO/DIN/AGMA |

|---|---|---|

| Densità della balla | 115-200 kg/m³ | ISO 11001 per la compressione delle macchine foraggere. |

| Resistenza del materiale | Rulli del tamburo a φ222 mm | DIN 8187 per la durata dei componenti nell'uso agricolo. |

| Emissione acustica | Sotto gli 85 dB | ISO 4871 per la sicurezza degli operatori sulle attrezzature da campo. |

| Valutazione di protezione | IP55 sui sensori | DIN 40050 per la resistenza alla polvere e all'acqua. |

| Precisione degli ingranaggi | Precisione dei denti a molla | AGMA 1106 per le tolleranze del meccanismo di prelievo. |

Fatti chiave (5 punti elenco)

- 🔵 Modello e aggancio: Rotopressa 9YG-1.0 con attacco di trazione e tipo di pick-up con denti a molla per una raccolta efficiente del foraggio.

- 🟠 Requisiti di alimentazione: Adatto a trattori da 48-80 kW a una velocità della presa di forza di 720 giri/min, con consumi ridotti per l'allineamento alle linee guida sull'efficienza EPA.

- 🔴 Specifiche delle balle: Forma balle da φ1100x1000 mm con densità di 115-200 kg/m³ tramite controllo tramite sensore, favorendo la conservazione nelle regioni umide del sud.

- 🟢 Dimensioni e peso: Misure 3750x2300x2020 mm in funzione con massa di 2840 kg, compatibile con il trasporto agricolo standard degli Stati Uniti.

- 🟣 Metriche delle prestazioni: Produce 40-100 balle/h a 5-20 km/h, favorendo la produttività delle aziende di medie dimensioni negli stati produttori di cereali.

Proposta di valore

La rotopressa per insilato 9YG-1.0 offre notevoli vantaggi operativi ai professionisti dell'agricoltura statunitense, migliorando l'efficienza e la facilità d'uso nella gestione della paglia. Tra le sue caratteristiche principali rientrano la compatibilità con i trattori di piccole dimensioni, consentendo una perfetta integrazione in strutture agricole compatte, comuni nel Midwest e nel Sud-Est, dove colture diversificate richiedono attrezzature adattabili. Inoltre, consente un consumo energetico ridotto rispetto ai modelli precedenti, riducendo così le spese di carburante e favorendo la conformità alle politiche nazionali di risparmio energetico. A livello più ampio, l'integrazione di sette funzionalità "human-friendly", come comandi ergonomici e miglioramenti della sicurezza, insieme a un dispositivo di alimentazione aggiornato, semplifica le attività quotidiane e riduce l'affaticamento dell'operatore. Nel complesso, a prezzi accessibili per le rotopresse, riduce le esigenze di manutenzione garantendo al contempo una compressione affidabile del foraggio, rendendola un'opzione intelligente per l'impiego di rotopresse per foraggio nei molteplici ambienti agricoli statunitensi.

- 🟠 Consumo energetico ridotto per un funzionamento conveniente con trattori di piccole dimensioni.

- 🔵 Dispositivo di alimentazione aggiornato per migliorare l'assunzione di materiale nelle applicazioni di mais, riso, grano e soia.

- 🟢 Sette funzioni umanizzate per una maggiore sicurezza e facilità d'uso sul campo.

Presse rotonde S9000 9YG-1.0 vs. 9YG-2.24D

Tabella di confronto

| Parametro | 9YG-1.0 | 9YG-2.24D S9000 |

|---|---|---|

| Nome del modello | Pressa rotonda 9YG-1.0 | Pressa per balle rotonde 9YG-2.24D (Modello base S9000) |

| Larghezza di ripresa | 1800 millimetri | 2240 millimetri |

| Larghezza della camera di compressione | 1000 millimetri | 1400 millimetri |

| Diametro della camera di compressione | φ1000 mm | φ1200 mm |

| Potenza corrispondente | 48-80 kW | 55-100 kW |

| Massa strutturale | 2840 chili | 4282 chili |

| Dimensioni complessive (LxWxH) | 3750x2300x2020 millimetri | 4240x3010x2450 mm (in funzione) |

| Dimensioni della balla (diametro x larghezza) | φ1100x1000 mm | φ1300x1400 mm |

| Densità della balla | 115-200 kg/m³ | 100-200 kg/m³ |

| Passo | 2045 millimetri | 2800 millimetri |

| Velocità operativa | 5-20 km/h | 5-35 km/h |

| Dimensioni della rete | 2000x1,0 m/balla | 2000x1,4 m/balla |

Guida alla selezione

Nella scelta di una pressa per insilato, valutare inizialmente la scala aziendale e i profili colturali regionali. Per operazioni compatte in aree come le Grandi Pianure, privilegiare unità compatibili con piccoli trattori, come il modello 9YG-1.0, che si integra con macchinari conformi all'EPA gestendo al contempo diversi tipi di paglia. Successivamente, valutare le esigenze di produttività: le 40-100 balle/h di questo modello sono adatte ad aziende agricole inferiori a 800 acri, concentrate su mais, riso, grano o soia. Considerare i parametri di densità: puntare a 115-200 kg/m³ per soddisfare i criteri di stoccaggio USDA per la prevenzione delle perdite. Valutare i fattori economici: i prezzi delle rotopresse di questa variante si adattano alla prudenza fiscale nelle zone cerealicole. Infine, confermare l'interoperabilità; verificare la presa di forza a 720 giri/min per mitigare le inefficienze dovute alle variazioni agronomiche statunitensi.

Fasi di installazione

- Posizionare la pressa su un terreno pianeggiante e fissarla al trattore tramite l'attacco di trazione, verificando che sia ben agganciata.

- Accoppiare l'albero della presa di forza a 720 giri/min, assicurandosi dell'allineamento delle scanalature.

- Inserire le reti (2000x1,0 m) nel distributore, verificando che il flusso non sia ostruito.

- Inizializzare il pannello del sensore per regolare la densità tra 115-200 kg/m³.

- Esaminare i rulli e le catene per verificarne l'adeguata lubrificazione, quindi effettuare un ciclo di inattività per valutare la funzionalità del tamburo.

- Calibrare l'elevazione del pickup per l'ottimizzazione dei denti elastici su superfici variabili.

- Eseguire una verifica completa della sicurezza, che comprenda i componenti di alimentazione aggiornati, prima dell'implementazione.

❓ Domande frequenti

- Cosa rende questa pressa per insilato adatta alle aziende agricole statunitensi? Il suo design per piccoli trattori favorisce un recupero efficiente della paglia in stati come l'Iowa, con una gestione versatile per più colture.

- Come si confrontano i prezzi delle rotopresse modello 9YG-1.0? Questo modello offre un prezzo di fascia media, solitamente inferiore alle alternative premium, garantendo al contempo prestazioni comparabili per le applicazioni delle macchine imballatrici per fieno.

- Quale manutenzione è necessaria per il pick-up a molla? Rimuovere i detriti dopo l'operazione; applicare lubrificante 80W-90 alle catene ogni 50 ore per evitarne il degrado nelle aride condizioni occidentali.

- Può gestire colture diverse in climi diversi? Sì, elabora efficacemente la paglia di mais, riso, grano e soia, come osservato nelle zone umide del sud.

- Con quale frequenza dovrei ispezionare il dispositivo di alimentazione? Eseguire revisioni trimestrali, in particolare prima del raccolto nelle regioni ricche di cereali, per mantenere aggiornate le funzionalità.

- Quale lubrificante è consigliato per la camera di compressione? Utilizzare olio sintetico VG220, sostituendolo ogni 500 ore per mantenere l'efficacia del tamburo.

- Come funziona il controllo della densità del sensore? Gestisce dinamicamente l'assemblaggio delle balle, modulando la compressione per ottenere produzioni costanti di 115-200 kg/m³ e riducendo al minimo le regolazioni.

- Questa pressa per foraggio è conforme agli standard ambientali? Promuove iniziative statunitensi attraverso la riduzione del consumo di energia e l'utilizzo efficiente della paglia, limitando le emissioni secondo le norme USDA.

- Quali vantaggi offrono le caratteristiche umanizzate? I sette miglioramenti, tra cui le interfacce ergonomiche, migliorano il comfort dell'operatore durante le sessioni prolungate nei campi del Midwest.

- Come risolvere il problema della densità non ottimale delle balle? Ricalibrare annualmente i sensori; verificare l'integrità della catena se i livelli scendono sotto i 150 kg/m³ con foraggio denso.

⭐ Recensione del cliente

Texas Farmer (John R., modello acquistato nel 2023): "Nella mia tenuta di 600 acri, il modello 9YG-1.0 si integra perfettamente con il mio trattore più piccolo e, la scorsa stagione, il ridotto consumo di potenza ha ridotto notevolmente le mie spese di carburante."

Operatore caseario della California (Maria S., promossa nel 2024): "Il dispositivo di alimentazione aggiornato gestisce senza problemi i residui delle nostre colture miste nella Central Valley; rappresenta un notevole passo avanti per l'efficienza quotidiana."

Midwest Hay Producer (Tom W., acquistato nel 2022): "Oltre ai prezzi competitivi delle rotopresse, la versatilità per la paglia di mais e di grano è impressionante: la densità rimane costante a 170 kg/m³."

Piccolo proprietario terriero del sud-est (Emily K., insediata nel 2025): "Ideale per i miei campi di soia; le sette funzioni umanizzate rendono il funzionamento meno faticoso, anche in condizioni climatiche umide."

Coltivatore di cereali delle pianure (Mike L., con sede negli Stati Uniti, modello 2023): "Questa pressa ottimizza il recupero della paglia di riso con un consumo energetico minimo, in linea con le nostre pratiche sostenibili e riducendo le perdite di 15%."

Proprietario di un allevamento di bestiame in Florida (Sarah P., acquistato nel 2024): "Elabora senza problemi le varianti di fieno pesante; il design indipendente garantisce durata, con semplici routine di manutenzione durante tutto l'anno."