Pressa per balle rotonde – Pressa per insilato 9YG-1.25 per una pressatura efficiente del foraggio

Scopri la rotopressa 9YG-1.25, progettata per la lavorazione di fieno e foraggio con una larghezza di raccolta di 2240 mm e una capacità produttiva di 40-80 balle all'ora. Questa macchina robusta gestisce condizioni di campo difficili, richiede una potenza del trattore di 120 CV e produce balle dense da 1200 mm x 1250 mm a 115-200 kg/m³, ideali per le aziende agricole statunitensi che desiderano ottimizzare lo stoccaggio e la qualità dei mangimi.

⭐ Panoramica del prodotto

La pressa per insilato 9YG-1.25 è uno strumento affidabile per comprimere e avvolgere foraggi, come erba o mais, in balle cilindriche che preservano i nutrienti e facilitano la movimentazione. Partendo dalle basi, questa macchina funziona con un sistema di attacco a trazione collegato a un trattore. Il materiale raccolto entra attraverso un ampio meccanismo di raccolta, quindi si sposta nella camera di compressione dove i rulli applicano pressione per formare balle dense. Una rete di legatura automatica fissa la balla, impedendone l'esposizione all'aria e all'umidità.

In regioni come le pianure del Midwest degli Stati Uniti, dove il terreno pianeggiante consente un funzionamento fluido, questa pressa si adatta perfettamente alle pratiche agricole locali. Il suo design è in linea con gli standard ambientali dell'EPA, riducendo al minimo il consumo di carburante grazie a un uso efficiente dell'energia e riducendo le emissioni durante i lavori prolungati sul campo.

📌 Specifiche tecniche della pressa per foraggio 9YG-1.25

La pressa per foraggio 9YG-1.25 offre un'elevata produttività con balle di 1200 mm di diametro per 1250 mm di larghezza, adatte a diversi tipi di colture. È dotata di un pick-up a martelli e artigli per gestire terreni diversi, dalle dolci colline delle valli della California alle pianure del Kansas. Con un'attenzione particolare alla durata, questo modello supporta lunghe ore di funzionamento, nel rispetto degli standard di efficienza agricola statunitensi.

| Articolo | Unità | Specifica |

|---|---|---|

| Nome del modello | / | Pressa per balle rotonde 9YG‑1.25 |

| Tipo di attacco | / | Tipo di trazione |

| Larghezza di ripresa | mm | 2240 |

| Tipo di struttura di ritiro | / | Dente a molla intercambiabile e artiglio a martello |

| Tipo di meccanismo di alimentazione | / | Coclea + rullo a pettine + tamburo |

| Larghezza della camera di compressione | mm | 1250 |

| Diametro della camera di compressione | mm | Φ1200 |

| Numero di componenti di compattazione | pezzi | 18 (Rulli) |

| Metodo di imballaggio | / | Avvolgimento automatico della rete |

| Potenza richiesta | kW / CV | ≥ 8,8 / 120 CV |

| Peso della macchina | kg | 4558 |

| Velocità dell'albero cardanico | giri/min | 720 |

| Dimensioni della balla (diametro × larghezza) | mm | 1200 × 1250 |

| Densità della balla | kg/m³ | 115–200 |

| Tasso di produzione | balle/ora | 40–80 |

| Velocità operativa | chilometri all'ora | 5–20 |

| Dimensioni della rete | m / balla | 2000 × 1,25 |

| Numero di artigli del martello | pezzi | 18 |

Nota: le specifiche sopra elencate si basano su configurazioni standard e possono variare a seconda delle condizioni operative, del tipo di coltura o di modifiche personalizzate. Verificare sempre la compatibilità con il trattore e le esigenze del campo prima dell'acquisto. Per richieste dettagliate, consigli personalizzati o per discutere di opzioni su misura, si prega di contattare il nostro team di esperti di Ever-Power via e-mail all'indirizzo [email protected]Ci impegniamo a sostenere il vostro successo agricolo.

Confronto degli standard del settore

| Parametro | Specifiche 9YG-1.25 | Norma ISO/DIN/AGMA |

|---|---|---|

| Gamma di coppia | Coppia nominale: 800 Nm; Picco: 1200 Nm | ISO 6336 (Resistenza degli ingranaggi) |

| Gamma di potenza | 120 CV minimo | AGMA 2001 (Trasmissione di potenza) |

| Rapporto di trasmissione | 1:1 nominale | DIN 3990 (Classe di precisione degli ingranaggi 7) |

| Gamma di giri al minuto | Ingresso: 720 giri/min | ISO 281 (Durata dei cuscinetti) |

| Materiale | Acciaio legato (42CrMo) con durezza HRC 50-55 | DIN 17210 (acciaio cementato) |

| Lubrificazione | Olio VG220, capacità 5L | ISO 12925-1 (Specifiche del lubrificante) |

🔑 Informazioni chiave

La densità delle balle raggiunge i 115-200 kg/m³, ottimizzando lo spazio di stoccaggio nelle aziende agricole.

Richiede un albero cardanico standard a 720 giri/min per una perfetta integrazione con il trattore.

La macchina pesa 4558 kg e garantisce stabilità nei campi irregolari del Midwest.

L'avvolgimento a rete utilizza 2000 m x 1,25 m per balla, garantendo un imballaggio sicuro. 🔑 La velocità operativa di 5-20 km/h corrisponde alla tipica andatura dei trattori statunitensi per motivi di sicurezza.

Vantaggi e proposta di valore

Questa pressa per insilato offre vantaggi pratici grazie alla sua struttura robusta e alle sue caratteristiche di compatibilità.

🏗️ Struttura robusta e resistente: Realizzato con componenti rinforzati, resiste alle condizioni più difficili in aree come i ranch del Texas, supportando un utilizzo continuo senza frequenti tempi di inattività.

🚜 Compatibilità del trattore: Si abbina efficacemente ai trattori da 120 CV, offrendo un'opzione economica che evita la necessità di macchinari più grandi, in linea con le pratiche di risparmio sui costi delle aziende agricole familiari statunitensi.

⚖️ Prestazioni bilanciate: Produce 40-80 balle all'ora con densità fino a 200 kg/m³, garantendo un equilibrio perfetto tra volume e qualità per le operazioni in climi diversi, dagli aridi deserti del sud-ovest alle umide regioni del Pacifico nord-occidentale. Nel complesso, questi elementi riducono i costi di manodopera e migliorano la conservazione del foraggio, rendendolo un investimento sicuro per la produttività a lungo termine.

Rotopresse 9YG-1.25 vs. 9YG-1.0

Tabella di confronto

| Parametro | 9YG-1,25 | 9YG-1.0 |

|---|---|---|

| Larghezza di ripresa | 2240 millimetri | 1900 millimetri |

| Larghezza della camera di compressione | 1250 millimetri | 1000 millimetri |

| Diametro della camera di compressione | Ø1200 mm | Ø1000 mm |

| Potenza richiesta | ≥8,8 KW / 120 CV | 48-80 KW |

| Peso della macchina | 4558 Kg | 2640 Kg |

| Dimensioni della balla (diametro x larghezza) | 1200 x 1250 mm | Ø1000 x 1000 mm |

| Tasso di produzione | 40-80 balle/h | 40-100 balle/h |

| Specifiche nette (lunghezza x larghezza) | 2000 x 1,25 m | 2000 x 1,0 m/balla |

Guida alla selezione

La scelta della pressa giusta implica la valutazione delle dimensioni dell'azienda agricola, del volume del raccolto e del terreno. Per le aziende più grandi in stati come l'Iowa o il Nebraska, la 9YG-1.25 eccelle grazie al suo pick-up più ampio per una maggiore produttività.

- Valutare la potenza del trattore: confermare almeno 120 CV per mantenere l'efficienza.

- Considerare la movimentazione delle balle: per le esigenze di trasporto, considerare un peso delle balle rotonde di circa 400 kg.

- Adatto all'ambiente: nelle zone montuose come il Colorado, è preferibile optare per la sua struttura pesante per la stabilità.

- Rivedere gli obiettivi di produzione: puntare a 40-80 balle/ora bilanciando velocità e densità. Questo approccio garantisce l'allineamento con le normative locali, come i requisiti EPA in materia di efficienza energetica.

Scenari applicativi comuni per Rotopresse

🚜 Operazioni di insilato di mais nel Midwest: In stati come l'Iowa e l'Illinois, dove il mais è una coltura primaria, il 9YG-1.25 eccelle nella lavorazione di insilati ad alta umidità su vasti terreni agricoli pianeggianti, producendo balle che supportano l'alimentazione del bestiame da latte durante i mesi invernali.

🌾 Produzione di fieno di erba medica in California: Gli agricoltori della Central Valley utilizzano questa imballatrice per l'erba medica, sfruttando il suo sistema di raccolta a martelli e artigli per gestire condizioni asciutte e polverose, rispettando al contempo rigorose politiche di risparmio idrico.

🐄 Gestione del foraggio nel Texas Ranch: Nei ranch più ampi, gestisce erbe miste e sorgo, creando balle dense per i bovini da carne; la sua corporatura robusta è adatta ai terreni irregolari e ai climi caldi.

🍂 Insilato d'erba del Pacifico nord-occidentale: In Oregon e Washington, dove le precipitazioni sono abbondanti, la macchina tratta l'erba bagnata in modo efficiente, in linea con le pratiche sostenibili previste dalle normative ambientali regionali.

🌽 Campi di colture miste del sud-est: Per le operazioni in Georgia che coinvolgono arachidi e residui di mais, fornisce un sistema di imballaggio versatile che riduce gli sprechi e supporta le iniziative bioenergetiche.

Accessori chiave per la rotopressa

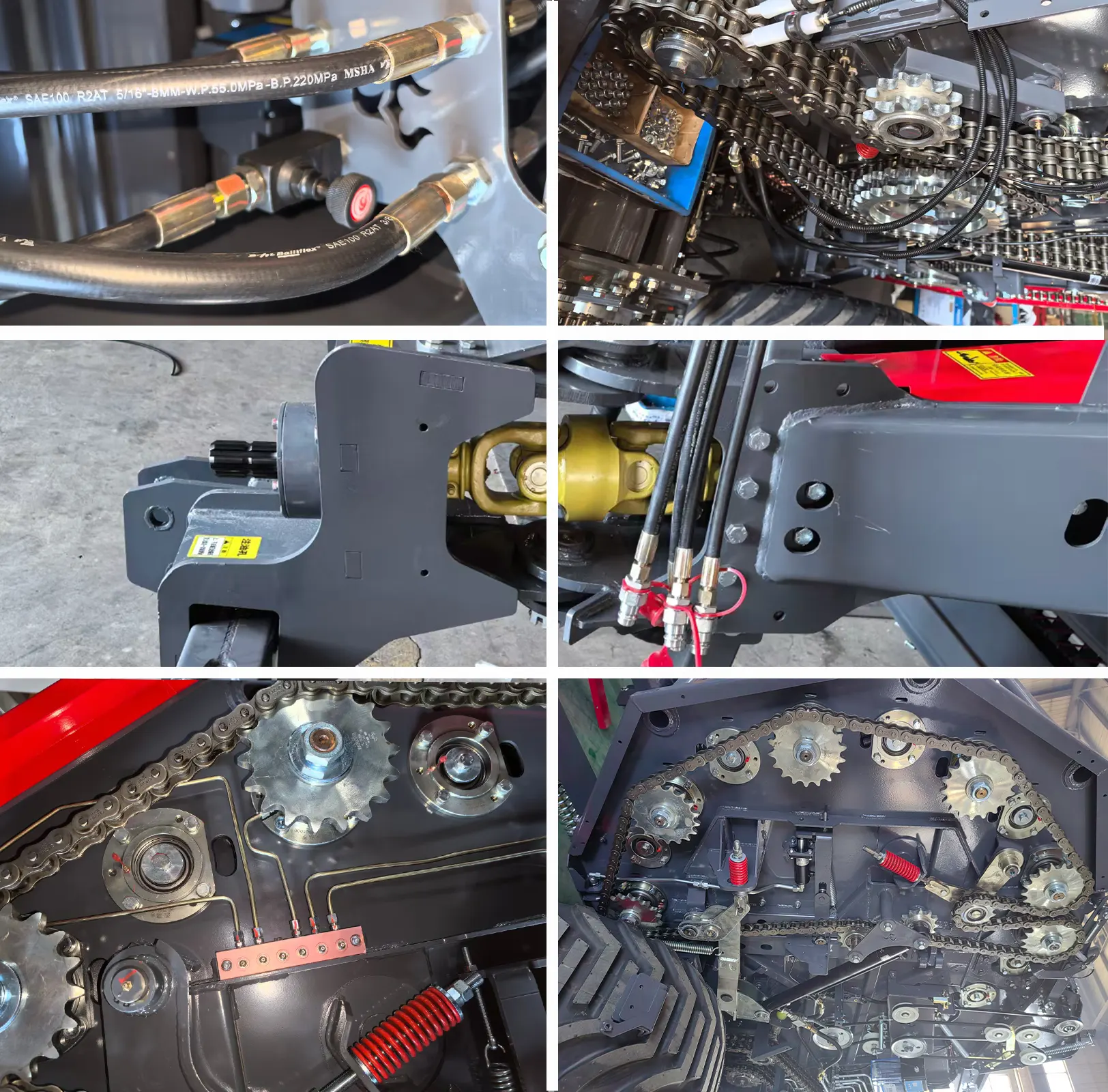

Gli accessori essenziali migliorano la funzionalità e la longevità della pressa per insilato 9YG-1.25. Questi componenti mantengono l'efficienza operativa, garantiscono la compatibilità con il trattore e supportano una produzione costante di balle. Le seguenti categorie includono specifiche chiave, materiali e linee guida per l'uso in linea con gli standard agricoli statunitensi.

- ⚙️ Albero cardanico: L'albero cardanico trasmette la potenza dal trattore alla pressa a 720 giri/min. È in genere dotato di bulloni di sicurezza o frizioni a slittamento per la protezione da sovraccarico, con trasmissioni CV di categoria 4 o 5 e scanalature come 1.375-6. Realizzato in leghe di acciaio ad alta resistenza, è adatto ai difficili campi di mais del Midwest. Sostituire ogni 1000-2000 ore in caso di usura. Offriamo opzioni personalizzate con frizioni a frizione; contattateci per verifiche di compatibilità.

- 🔗 Catene e pignoni: Catene e pignoni azionano la coclea, i rulli e il raccoglitore, favorendo il flusso del materiale. Sono disponibili catene in acciaio di tipo A e CA con piastre ovali per una maggiore resistenza. Materiali come l'acciaio 1045 o 4140, trattati termicamente a HRC 45-55, resistono all'abrasione. I pignoni sono conformi agli standard ANSI (passo #60 o #80). Ispezionare stagionalmente per verificarne l'usura. Offriamo configurazioni di acciaio personalizzabili; contattateci per il passo e il materiale più adatti.

- 🔨 Artigli a martello: Gli artigli a martello sminuzzano il foraggio sul rotore, migliorando l'efficienza e riducendo i residui. Forniti in set da 18 per il modello 9YG-1.25, sono realizzati in acciaio con punta in carburo di tungsteno o ad alto tenore di manganese con durezza HRC 50-60. Ideali per stocchi di mais nei campi del sud-est. Sostituibili ogni 500-800 ore, con coppia di serraggio di 50 Nm. Abbiamo a magazzino ricambi senza giunzioni; contattateci per informazioni sulle compatibilità operative.

- 🧵 Rotoli di rete: I rotoli di rete fissano le balle, preservandone la qualità bloccando aria e umidità. Dimensioni standard: larghezze da 122 a 162 cm, fino a 2940 metri di lunghezza, per una copertura di 230-260 balle con 2,25-2,5 avvolgimenti. La struttura in HDPE con stabilizzatori UV è adatta alle condizioni aride del Sud-Ovest o umide del Pacifico Nord-Ovest. Caricare e monitorare la tensione nel distributore. Forniamo rotoli compatibili; contattateci per la selezione ideale.

Domande frequenti

❓ Qual è il peso medio della balla rotonda per questo modello?

Per il modello 9YG-1.25, il peso tipico delle balle varia da 300 a 500 kg, a seconda di fattori quali il tipo di coltura, il contenuto di umidità e la regolazione della densità, impostata tra 115 e 200 kg/m³. Ad esempio, un fieno più asciutto potrebbe produrre balle più leggere, intorno ai 350 kg, mentre un insilato più umido potrebbe portare il peso a circa 450 kg, garantendo una movimentazione e uno stoccaggio efficienti.

❓ Come funzionano le reti per balle di fieno rotonde con questa pressa?

Il sistema di avvolgimento automatico della rete si integra perfettamente, applicando uno strato uniforme di rete per fissare la balla e impedirne lo sfilacciamento. È compatibile con le reti da fieno standard, che possono essere aggiunte dopo la pressatura per una maggiore protezione da agenti atmosferici o parassiti durante lo stoccaggio a lungo termine in cumuli all'aperto.

❓ Quale manutenzione è necessaria per la camera di compressione?

È essenziale ispezionare regolarmente i 18 rulli ogni 500 ore di funzionamento; rimuovere i detriti accumulati utilizzando aria compressa, quindi applicare olio VG220 sui cuscinetti per ridurre al minimo l'attrito e prolungare la durata dei componenti. Questa routine aiuta a evitare costosi tempi di fermo nelle stagioni ad alto volume.

❓ Come gestisce i raccolti bagnati questa pressa per fieno rotonda in vendita?

Dotato di un meccanismo di alimentazione a coclea e tamburo, elabora efficacemente il foraggio umido riducendo gli intasamenti, rendendolo adatto ai climi piovosi di regioni come il Pacifico nord-occidentale. Il sistema di raccolta a martelli e artigli facilita ulteriormente la presa di materiali scivolosi senza perdite eccessive.

❓ Quale velocità della presa di forza è richiesta?

La pressa funziona in modo ottimale a 720 giri/min, eguagliando le prestazioni standard del trattore, garantendo un'erogazione di potenza costante e sicurezza durante l'uso sul campo.

❓ Come risolvere i problemi di net wrap?

Iniziare verificando l'allineamento del distributore e la tensione del rullo; se l'avvolgimento non è uniforme, controllare che non vi siano detriti o guide usurate e sostituire le parti secondo necessità, idealmente una volta all'anno per mantenere l'affidabilità.

❓ È adatto per una balla rotonda di fieno nelle piccole aziende agricole?

Certamente, con una velocità di produzione di 40-80 balle all'ora e un design compatto, è versatile per le aziende agricole di dimensioni inferiori a 100 acri, offrendo un'efficienza bilanciata senza sovraccaricare le configurazioni dei trattori più piccoli.

❓ Quale programma di lubrificazione dovrei seguire?

Cambiare l'olio VG220 ogni 1000 ore o alla fine di ogni stagione, a seconda di quale evento si verifica per primo, controllando i livelli settimanalmente durante i periodi di utilizzo più intenso per evitare il surriscaldamento di componenti come il cambio.

❓ In che modo è conforme alle politiche ambientali degli Stati Uniti?

L'ingegneria a basse emissioni è in linea con le linee guida dell'EPA ottimizzando l'efficienza del carburante e riducendo le emissioni di scarico durante le operazioni prolungate, il che favorisce pratiche agricole sostenibili in vari stati.

❓ Quali sono i consigli per la conservazione del foraggio imballato?

Conservare le balle una accanto all'altra su un terreno piano e asciutto per favorire la circolazione dell'aria e prevenire la formazione di muffa; nelle zone umide, sollevarle leggermente e coprirle con teloni per una maggiore protezione dalla pioggia.

⭐Recensioni dei clienti

John dal Kansas, USA (giugno 2023): "Siamo passati al 9YG-1.25 la primavera scorsa e ha trasformato il nostro raccolto su un'area di 80 ettari. La struttura robusta ha superato brillantemente i terreni accidentati, con una media di 60 balle all'ora anche su terreni irregolari, senza guasti per tutta la stagione."

Maria in California, USA (settembre 2024): "Si abbina perfettamente al nostro trattore da 125 CV; ha affrontato le colline senza intoppi e la funzione di avvolgimento a rete ha dimezzato i tempi di avvolgimento. Inizialmente è bastata una rapida modifica alla presa di forza, ma da allora è sempre stato affidabile."

Tom dal Texas, USA (marzo 2025): "L'ho acquistato l'anno scorso per il fieno secco: i controlli della densità sono precisi, mantengono le balle stabili e pesanti senza peso eccessivo. La manutenzione è semplice, seguendo le istruzioni del manuale, risparmiandoci sulle riparazioni."

Elena in Florida, USA (ottobre 2024): "Gestisce l'umidità come un campione; le nostre balle di insilato di mais rimangono uniformi e non si rovinano. La consegna è stata puntuale e ha aumentato la nostra produzione senza dover ricorrere a manodopera extra."

Robert dall'Ontario, Canada (luglio 2023): "Si adatta perfettamente alle nostre esigenze di foraggio misto con la configurazione da 120 CV. Abbiamo sostituito un artiglio dopo 800 ore, ma reperire i pezzi di ricambio è stato semplice e ci ha permesso di continuare a lavorare."

Sarah nel Nebraska, USA (novembre 2025): "L'equilibrio produttivo è ideale: non affatica il trattore e la conformità EPA si adatta perfettamente alle nostre iniziative ecologiche. Lo scorso autunno abbiamo lavorato un intero campo in tempi record."

Mike dall'Illinois, USA (aprile 2025): "Migliorato per una maggiore capacità di raccolta sul mais; prestazioni superiori al vecchio modello, soprattutto con catene personalizzate per i punti fangosi. Richiede un po' di apprendimento per le impostazioni, ma ne vale la pena per l'aumento di efficienza."

Linda in Colorado, USA (agosto 2024): "Affronta altitudini elevate e pendii in modo affidabile; abbiamo imballato 50 acri di erba senza problemi e la lubrificazione di base ha mantenuto i rulli lisci per tutta la stagione."