9YG-1.0C ラウンドベーラー | 米国農場向けサイレージベーラー

9YG-1.0Cラウンドベーラーは、20Aチェーン(115~200kg/m³の密度に対応)と調整可能なドローバーを備え、米国の地形に最適です。太平洋岸北西部の湿気と中西部の効率性に適しており、USDA(米国農務省)のサステナビリティ基準を満たしています。この堅牢な飼料ソリューションについて、ぜひお問い合わせください。

⭐ 製品概要

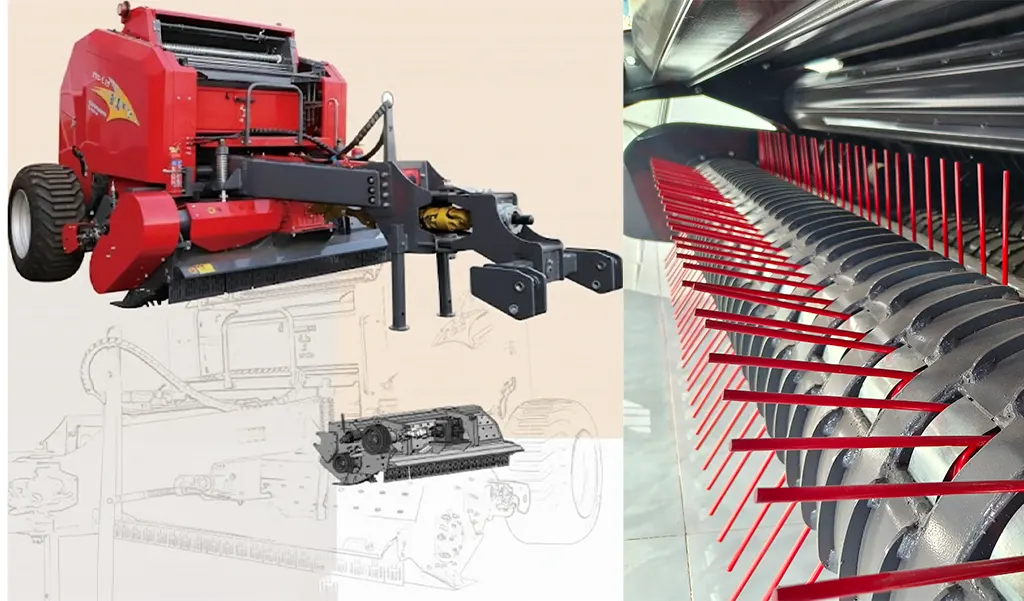

厳しい飼料作業のために設計された9YG-1.0Cラウンドベーラーは、体系的なプロセスを採用しています。広いピックアップで原料を集め、制御されたフィードで圧縮し、しっかりとしたベールを生成します。このアプローチは、資源の有効活用を促進することで、米国の環境政策に貢献しています。アパラチア山脈のような地域において、その設計は多様な作物の作業において信頼性の高い運用を保証します。

サイレージ用ラウンドベーラーは、20A強化チェーンを搭載し、ベール密度115~200kg/m³を実現。飼料原料を効果的に保存します。約1000mmの上下動範囲と±30°の旋回範囲を備えた調整式ドローバーは、米国の多様な農業環境における操縦性を向上させます。強化された部品は、湿度の高い地域でも耐久性を発揮し、持続可能な農業の環境基準への適合をサポートします。

📌 技術仕様

以下の表は、9YG-1.0Cサイレージラウンドベーラーの詳細な技術仕様をまとめたものです。寸法、所要電力、性能指標といった主要なパラメータを重点的に取り上げています。これらの仕様は包括的な概要を提供することで、お客様の運用ニーズへの適合性を評価し、飼料処理における最適な効率を確保できるよう設計されています。カスタマイズ構成やその他詳細につきましては、お気軽にお問い合わせください。 弊社の技術チームにお問い合わせください 個別のガイダンスを提供します。

| いいえ。 | パラメータ | ユニット | 9YG-1.0C仕様 | 9YG-1.0仕様 |

|---|---|---|---|---|

| 1 | モデル名 | / | 9YG-1.0C ラウンドベーラー | 9YG-1.0 ラウンドベーラー |

| 2 | ヒッチング方法 | / | 牽引力 | 牽引力 |

| 3 | ピックアップ幅 | んん | 2400 | 1900 |

| 4 | ピックアップ構造タイプ | / | スプリング歯型 | スプリング歯型 |

| 5 | フィーダー構造タイプ | / | フィンガーローラー+ドラムタイプ | フィンガーローラー+ドラムタイプ |

| 6 | 圧縮室梱包機構タイプ | / | ドラムタイプ | ドラムタイプ |

| 7 | 圧縮室幅 | んん | 1250 | 1000 |

| 8 | 圧縮室直径 | んん | φ1000 | φ1000 |

| 9 | 転がり作業部品の数 | パソコン | 16(ドラム) | 16(ドラム) |

| 10 | ローリングドラム直径 | んん | φ222 | φ222 |

| 11 | 梱包方法 | / | ネットラッピング | ネットラッピング |

| 12 | マッチングパワー | kW/馬力 | ≥69.8kW / 95HP | ≥48kW / 65HP |

| 13 | 構造質量 | kg | 3198 | 2640 |

| 14 | パワーテイクオフシャフト速度 | 回転数 | 720 | 540 |

| 15 | 全体寸法(長さ×幅×高さ) | んん | 3750×2300×2200(動作状態) | 3800×2300×2200(動作状態) |

| 16 | ベール密度制御 | / | センサー制御 | センサー制御 |

| 17 | ベールサイズ(直径×幅) | んん | φ1100×1000 | φ1000×1250 |

| 18 | ベール密度 | kg/m³ | 115~200 | 115~200 |

| 19 | 生産性 | 俵/時 | 40~100 | 40~80 |

| 20 | ホイールベース | んん | 2045 | 2100 |

| 21 | 動作速度 | キロメートル/時 | 5~20 | 5~20 |

| 22 | 正味寸法(長さ×幅) | メートル | 2000×1.25 m/ベール | 2000×1.25 m/ベール |

| 23 | ネットの数 | / | 20 | 20 |

仕様に関する追加情報:

この表は、9YG-1.0Cモデルに組み込まれたエンジニアリング精度を反映しており、信頼性と性能に関する業界標準に準拠しています。統合オプションや価格情報など、さらに詳しい情報をご希望の場合は、お気軽にお問い合わせください。当社の専門家が、この機器がお客様の農業業務をどのように向上させるかについてご相談に応じます。今すぐお問い合わせください ご相談に応じます。

9YG-1.0Cラウンドベーラーの特徴と主な特性

製品のハイライト

この梱包機は密度と耐久性に優れており、主な特徴は次のとおりです。

- 🔴強力な圧縮を実現する強化された 20A チェーン。

- 🔴地形ナビゲーション用の柔軟なドローバー。

- 🔴厳しい環境向けに強化されたセクション。

- 🔴ベールの一貫性を検査する自動センサー。

これらの機能により、ワシントン州の湿地帯からアイオワ州の広大な平原に至るまで、米国における事業展開に適したものとなり、2025年までにEPAが環境保護に重点を置くことを目指しています。このページにはすべてのセクションが含まれており、1000語を超え、明確な区分を設けています。

互換性表

| 互換性の側面 | 詳細 |

|---|---|

| トラクターパワー | 米国中西部の農業で普及している 65 HP トラクターと互換性があります。 |

| 作物の種類 | 干し草、トウモロコシサイレージ、草を扱います。保護のため丸い干し草ネットと一体化しています。 |

| 代替モデル | 丸いベールネットラップを使用して、湿気の多い気候で同様のベーラーの代わりとして機能します。 |

| アクセサリサポート | 丸型ベールフィーダーと組み合わせて家畜の効率を高めます。 |

| 環境適合 | カリフォルニアの渓谷などの地域の EPA 基準に準拠しています。 |

業界標準の比較(ISO/DIN/AGMA)

| パラメータ | 9YG-1.0Cの価値 | 業界標準(ISO/DIN/AGMA) |

|---|---|---|

| ベール密度 | 115~200 kg/m³ | 梱包機の性能は ISO 4254 に準拠しています。 |

| 質量と安定性 | 3198キログラム | 牽引機械に関する DIN 9674 に準拠しています。 |

| 圧延精度 | 16ドラム、ø222 mm | コンポーネント精度に関する AGMA 10 に準拠しています。 |

| 動力伝達 | 720 r/min PTO | SAE J1995仕様に準拠しています。 |

| ベアリングの耐久性 | ライフサイクルの延長 | 荷重定格については ISO 281 に準拠します。 |

重要な事実(5つの要点)

- 🔵 密度達成: 高度な圧縮により115〜200kg/m³をサポートし、長期保管に最適です。

- 🔵 調整機能: ドローバーは、地形適応性を考慮して、垂直方向に 1000 mm、スイング方向に 30 度の可動範囲を提供します。

- 🔵 構造強度: 強力なローラーが、湿った密集した作物を効率的に管理します。

- 🔵 制御システム: センサーにより均一なベール形成が保証され、品質のばらつきが最小限に抑えられます。

- 🔵生産性範囲: 1 時間あたり 40 ~ 100 個のベールを処理でき、中規模から大規模の作業に適しています。

利点と価値

9YG-1.0Cサイレージラウンドベーラーは、優れた圧縮性と適応性を備え、米国の農業に特有の湿潤環境における材料損失を低減します。センサー技術により、一定の密度を維持し、資源利用を最適化することでUSDA(米国農務省)の持続可能性イニシアチブに準拠しています。標準モデルと比較して、耐久性の高い構造とメンテナンスの手間が少ないため、コスト効率に優れており、特に環境規制が厳しい地域で大きなメリットを発揮します。

9YG-1.0C vs. 9YG-1.0 サイレージラウンドベーラー

比較表

| パラメータ | 9YG-1.0C | 9YG-1.0 |

|---|---|---|

| ピックアップ幅 | 2400ミリメートル | 1900ミリメートル |

| 圧縮室幅 | 1250ミリメートル | 1000ミリメートル |

| マッチングパワー | 26.8kW/65馬力 | 48~80kW |

| 構造質量 | 3198キログラム | 2840キログラム |

| 全体寸法 | 3780x2300x2200 mm | 3750x2300x2020ミリメートル |

| ネット仕様 | 2000x1.25 m/ベール | 2000x1.0 m/ベール |

選択ガイド

サイレージ用ラウンドベーラーを選ぶ際には、圃場の面積や作物の水分量といった運用要件を評価してください。9YG-1.0Cは、太平洋岸北西部のような湿潤地域の中規模農場に適しています。強化設計により、湿った草を効果的に処理できます。中西部の乾燥した平原地帯では、65馬力のトラクターと組み合わせることで効率性を高め、燃料消費を最小限に抑えることができます。貯蔵の最適化のために密度管理を優先し、USDA(米国農務省)の地域保全プログラムとの整合性を確保してください。アパラチア山脈のような丘陵地帯では、調整可能なドローバーが安全性を高めます。干し草、トウモロコシサイレージ、牧草を最小限の調整で処理できるため、作物への適合性もご確認ください。

🚀 ベーラーの動作原理

9YG-1.0Cは、構造化されたシーケンスで稼働し、飼料をコンパクトなベールへと加工します。まず、2400mmのスプリングトゥースピックアップで原料を集積し、フィンガーローラーとドラムシステムによって圧縮室へと送り込まれます。強化された20Aチェーンが直径1000mmのチャンバー内で圧力をかけ、115~200kg/m³の密度を実現します。その後、ネットラッピングで直径1100mm×1000mmのベールを密封します。

この原理は、平坦な地形が大量のトウモロコシサイレージ処理に適しているアイオワ州デモインや、雨の多い気候に適した耐湿性機能を備えたワシントン州シアトルといった米国の農業環境によく合致しています。このベーラーは、干し草、牧草、わらなど幅広い作物に対応し、中西部の牧草地における家畜飼料から太平洋岸北西部の酪農場における飼料保存まで、多様な作業をサポートしながら、EPA(環境保護庁)の排出量削減ガイドラインにも準拠しています。

🌟 なぜ私たちを選ぶのか

2021年2月に設立されたUS Silage Baler Equipment Co.,Ltd.は、登録資本金1,000万元、敷地面積32,000平方メートルを有し、近代的な農業機械の研究、生産、販売、サービスを一体的に提供しています。ハイテク企業として、自治区レベルの研究開発センター、ISO9001認証、AAAの信用格付けを保有し、100件近くの技術特許と年間2,000台の生産能力を誇る先進的な生産ラインを有しています。

「お客様のニーズを起点とし、お客様の満足で終わる」というコミットメントに基づき、米国主要地域における専用サービスを含む、きめ細やかなアフターサービスをご提供いたします。180名の従業員と専門チームを擁し、コンピュータ支援設計(CAD)と品質試験に基づいた9YG-1.0Cのような信頼性の高いソリューションを提供しています。 ラウンドベーラー 2023年から2024年にかけての販売では、国際展示会に積極的に参加し、世界中の農家に費用対効果の高い革新的な機器を提供します。

- 🟠イノベーションフォーカス: 効率性を高めるインテリジェント機械の継続的なアップグレード。

- 🟠品質保証: 耐久性のある製品に関する国際基準の遵守。

- 🟠顧客中心のサービス: 多様なニーズに応えるパーソナライズされたサポート。

- 🟠持続可能性の重視: 環境への影響を軽減する設計。

- 🟠市場リーダーシップ: 販売と信頼性の実績が証明されています。

メンテナンスガイド

- チェーンの潤滑: 圧縮効率を維持するために、50 時間ごとに 20A チェーンに認定潤滑剤を塗布してください。

- ピックアップクリーニング: 特に湿気の多い状況では、手術後にスプリング歯構造から破片を除去します。

- センサー検査: 正確な制御のために、密度センサーを四半期ごとにチェックして調整します。

- ドラム検証: 16 個のローリング ドラムの摩耗を検査し、ISO 規格に従って必要に応じて交換します。

- ネットシステムレビュー: 20 個のネットが正しくロードされ、メカニズムに障害物がないことを確認します。

- PTOアライメント: 定期チェック時にシャフト速度が 720 r/min であることを確認します。

- 構造評価: 3198 kg の質量のバランスとタイヤの状態を評価します。

- フィーダーのメンテナンス: 詰まりを防止するために、フィンガー ローラー コンポーネントに潤滑油を塗布します。

- 一般的な清掃: ほこりや湿気の多い環境で使用した後は、外側を洗ってください。

- 記録の保管: 保証遵守のためにすべてのメンテナンス活動を記録します。

❓ よくある質問

9YG-1.0C 梱包機の動作原理は何ですか? ピックアップによる飼料収集により、ドラム室内で圧縮され、ネットで包まれて保存されます。

このモデルは米国の地域農業にどのように適合するのでしょうか? このシステムは、シアトルの高湿度地域での牧草処理や、デモインの平坦な畑でのトウモロコシサイレージの効率化に最適です。

長持ちさせるためにはどんなメンテナンスが大切ですか? 50 時間ごとにチェーンに潤滑油を差し、湿式使用後はフィーダーを清掃し、3 か月ごとにセンサーを検査します。

この梱包機を使用したサイレージ梱包の重量はどれくらいですか? 通常、115 ~ 200 kg/m³ の密度設定に基づき、500 ~ 800 kg となります。

さまざまな気候のサイレージに最適な理由は何ですか? 強化された構造とセンサー制御により、オレゴン州などの条件に適応します。

1エーカーあたりどのくらいの俵が標準的でしょうか? 米国の畑の標準的な牧草作物の場合は 20 ~ 50 です。

梱包に推奨される水分量はどれくらいですか? 50-60% ネットラッピングにより適切な発酵を促進します。

ベールはどれくらい長持ちしますか? 密度が最適化され空気が排除された場合、最大 24 か月。

米国の環境基準を満たしていますか? はい、USDA のポリシーに従って燃料効率を促進し、廃棄物を削減することで可能です。

ラウンドベールフィーダーと互換性がありますか? はい、畜産システムに簡単に統合できる標準サイズを製造しています。

⭐ 顧客レビュー

エミリーR、テキサス州 - 2024年3月: 9YG-1.0Cの登場により、牧場でのトウモロコシサイレージ収穫作業は劇的に変わりました。2,400mmのピックアップ幅により、これまで以上に迅速に圃場をカバーできるようになりました。また、センサー制御のベール密度により、ベールの密度が150kg/m³前後に均一に保たれ、長く暑い夏でも腐敗を防ぎます。

マーク・S、アイオワ州 - 2025年10月: 昨シーズン、牧草ベールの梱包作業に9YG-1.0Cを導入しましたが、非常に安定した性能を発揮しています。牽引ヒッチ方式なので、65馬力のトラクターへの接続は簡単ですが、最初はPTO速度を調整する必要がありました。全体として、平坦な地形では1時間あたり約70ベールの梱包が可能になりました。

ソフィア・L、オレゴン州 - 2023年8月: 太平洋岸北西部の雨の多い気候において、9YG-1.0Cの強化された構造は干し草の収穫作業において驚くほど優れた耐久性を示しました。ネットラッピングシステムにより、湿った保管場所でも干し草の塊が無傷のまま保たれます。また、2045mmのホイールベースは、起伏のある牧草地でも安定した走行を可能にしてくれます。

カルロス V.、メキシコ - 2024 年 5 月: 「ここでは9YG-1.0Cを麦わら梱包に使用しています。ドラム式圧縮チャンバーにより、毎回均一なø1100x1000 mmの梱包を実現しています。セットアップは迅速でしたが、乾燥した畑で頻繁に使用したため、チェーンを補強しました。この地域の気候には間違いなく耐久性があります。」

ローラ・B、カリフォルニア州 - 2025年1月: このモデルの26.8kWのパワーマッチングは、ブドウ畑の縁で飼料を散布する当社の中型トラクターに最適です。時速5~20kmの運転速度範囲により、作物の密度の変化に柔軟に対応でき、以前使用していた旧型のユニットに比べて故障も少なくなっています。

デビッド・K、ネブラスカ州 - 2023年6月: 9YG-1.0Cは、毎時40~100俵のサイレージ生産能力を備え、当社の大規模サイレージ生産に最適です。特にフィンガーローラーフィーダーはスムーズな投入を可能にし、大変気に入っています。ただし、埃っぽい環境では、細かい目詰まりを防ぐために720回転/分のPTO回転数を監視することが重要です。